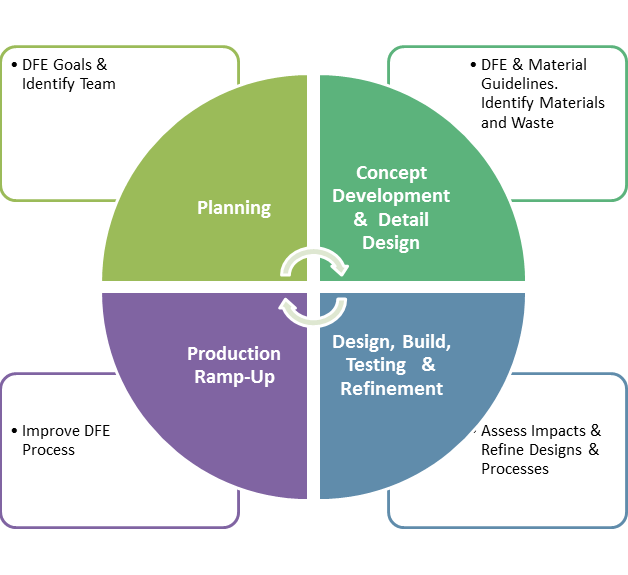

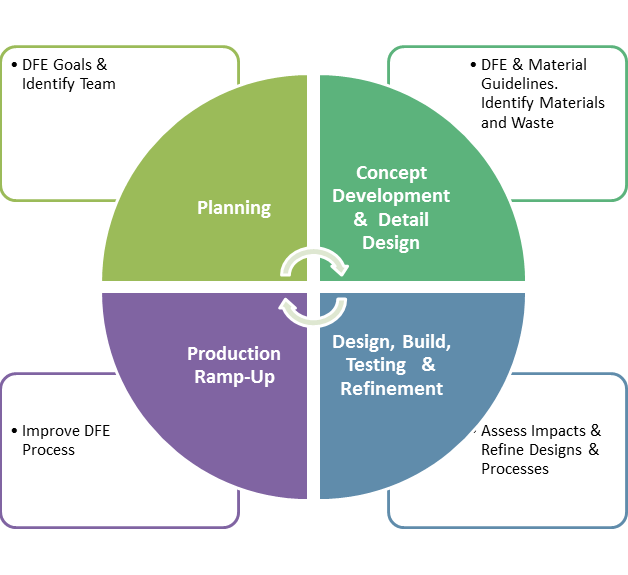

We’re living in an era that is plagued by buzzwords such as Global Warming, Rising Pollution Indices, Resource Depletion, Fresh Water Shortage and Land Degradation. We clearly are moving to a state where the rising sea levels will engulf a large part of the land in another 100 years from now .The rate at which carbon dioxide is being dumped into the environment is 1000 tons per second and the last two decades of the 20th century have been the hottest in the last 400 years.There’s a clear corporate responsibility for all businesses and product manufacturers to design their products & services for environmental sustainability by incorporating better product and service design processes. Digital Technology and Digital Transformation projects can play a big role here and has great potential to address many of the current challenges facing the world. Industries are moving towards a service oriented model with the perfect example of Uber and Amazon, wherin with the help of cloud and other Web & AI technologies there’s aggregation of resources and more optimized usage of resources which itself is a disruptive solution for reducing energy usage and wastage.Designing for the environment is merely a process that you need to incorporate into your product design & digital transformation strategy, in time it becomes a way of thinking and a thumb rule for innovation. There are softwares that can be used for LifeCycle Assessment such as OpenLCA, Sustainable Minds, SimaPro etc. OpenLCA is an Opensource Tool that is freely available for use. OpenLCA can be used by industries, consultancy companies, education and for research.Once the Lifecycle Assessment is done, DFE can then be incorporated into your product development process as below.

There are softwares that can be used for LifeCycle Assessment such as OpenLCA, Sustainable Minds, SimaPro etc. OpenLCA is an Opensource Tool that is freely available for use. OpenLCA can be used by industries, consultancy companies, education and for research.Once the Lifecycle Assessment is done, DFE can then be incorporated into your product development process as below. For Manufacturing Companies 4 Key Things to Evaluate at the end of the DFE Design Process are:

For Manufacturing Companies 4 Key Things to Evaluate at the end of the DFE Design Process are:

How do we go about doing this?

Let’s look at four simple Designing For Environment (DFE) Rules that can be incorporated into your product design & strategy.- Design products and processes with industrial materials that can be recycled continually

- Use natural materials as much as possible for raw materials that can be returned to earth’s natural cycles. Wherever possible reduce the Carbon Footprint of your services.

- Design products and processes that DO NOT create unnatural/toxic materials that can contaminate the environment.

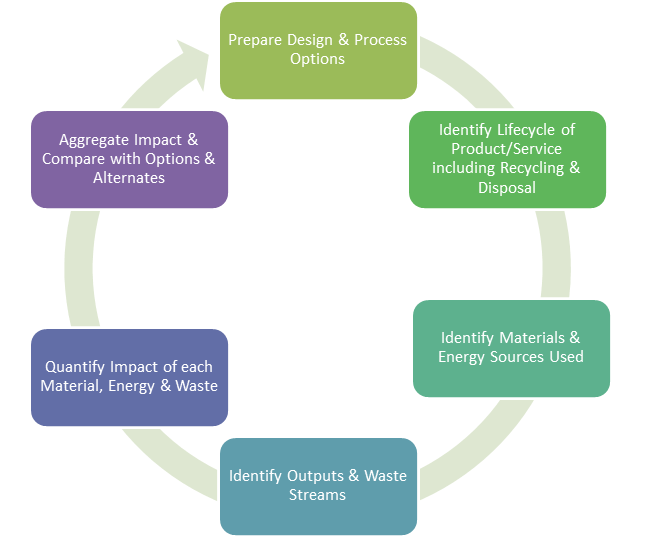

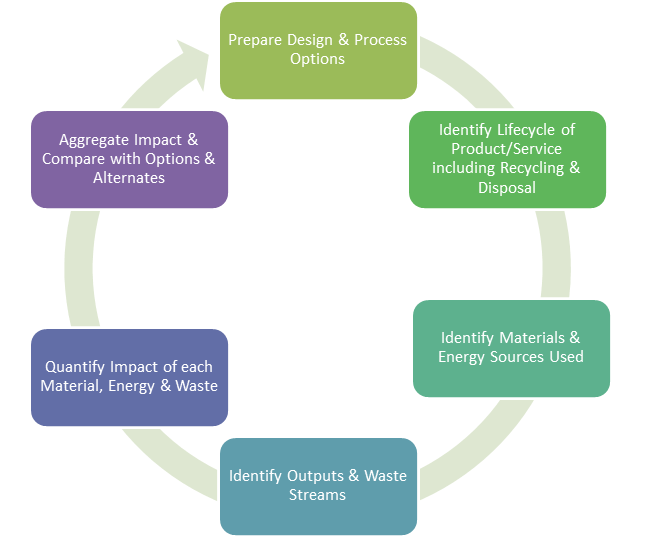

- Design products and processes with clean, renewable sources of energy rather than that uses fossil fuels. Designing processes and products with the above 4 rules requires a conscious effort in each step of product or service creation. The first step here is to do a Life Cycle Assessment of your product.

Life Cycle Assessment

There are softwares that can be used for LifeCycle Assessment such as OpenLCA, Sustainable Minds, SimaPro etc. OpenLCA is an Opensource Tool that is freely available for use. OpenLCA can be used by industries, consultancy companies, education and for research.Once the Lifecycle Assessment is done, DFE can then be incorporated into your product development process as below.

There are softwares that can be used for LifeCycle Assessment such as OpenLCA, Sustainable Minds, SimaPro etc. OpenLCA is an Opensource Tool that is freely available for use. OpenLCA can be used by industries, consultancy companies, education and for research.Once the Lifecycle Assessment is done, DFE can then be incorporated into your product development process as below. For Manufacturing Companies 4 Key Things to Evaluate at the end of the DFE Design Process are:

For Manufacturing Companies 4 Key Things to Evaluate at the end of the DFE Design Process are:- Material Chemistry

- Recycled Content Percent

- Disassembly Percent

- Recyclability Percent

- Dunlop boots developed a line of recycled boots that takes back used Wellington boots from customers to reduce production of new PVC and keeps it out of the Waste Stream.

- Herman Miller incorporated Environment Goals such as Zero Hazardous Waste Generation, Zero Air & Water Polluter Emissions, 100% Green electrical use, 100% Sales from DFE products & also constructed company buildings for a minimum LEED Silver Certification.

- A service sharing platform provided by Uber, AirBnb, Lyft have created a service industry for shared resources for renting, sharing, swapping or lending their idle goods.

- Products as a Service launched by Philips wherein you can ‘pay by lux’ to charge for lighting by output instead of unit sales.

- Proctor & Gamble now operates 45 facilities on a zero-waste basis, which has created more than $1 billion in value for the company over the past five years.

- Panasonic operates a high-tech disassembly, reuse and recycling plant, thereby recycling around 700,000 products a year.